But to make hub motors viable, there are some hurdles that need to be cleared.

#Siemens vdo lower stator drivers

Of course, this attitude doesn’t take into account human ingenuity, technological advances, and that over the last 100 years, there have been few incentives to wean drivers from gas-powered cars. “If they haven’t found success yet, it’s unlikely they ever will due to the problems they have.” At least that’s the feeling of one researcher at an organization dedicated to electric vehicles. Hub motors have been around for more than a century, and the fact they haven’t caught on speaks for itself. It might also turn out that new features in development such as lane following, collision avoidance, and active cruise control would be easier to implement with separate wheel motors and a master controller. For example, having the right wheels turn one way and the left wheels turn the opposite direction could give a car a near-zero turning radius for getting out of tight parking spots. There’s even the possibility of adding new, previously impossible, or at least impractical, features. This means features such as antilock brakes, traction control, and even cruise control could be handled by a single master controller.

The spinning wheels slow down as they are forced to work against the electromagnetic fields to create electricity.

#Siemens vdo lower stator generator

Hub motors can be used as brakes by acting as a generator rather than a motor.Either way, doing away with the transmissions found in most cars means less weight, less complexity, and more efficiency. But there are some designs that use simple, relatively lightweight planetary-gear transmissions to let them run more efficiently at higher rotational speeds. So most hub-motor designs do away with transmissions, letting the electric motor’s flat torque curve do the work. By comparison, ICEs need to be revving beyond 1,000 rpm to create enough torque to get a car or truck moving.

Like most electric motors, hub motors generate high torque at low rpms.

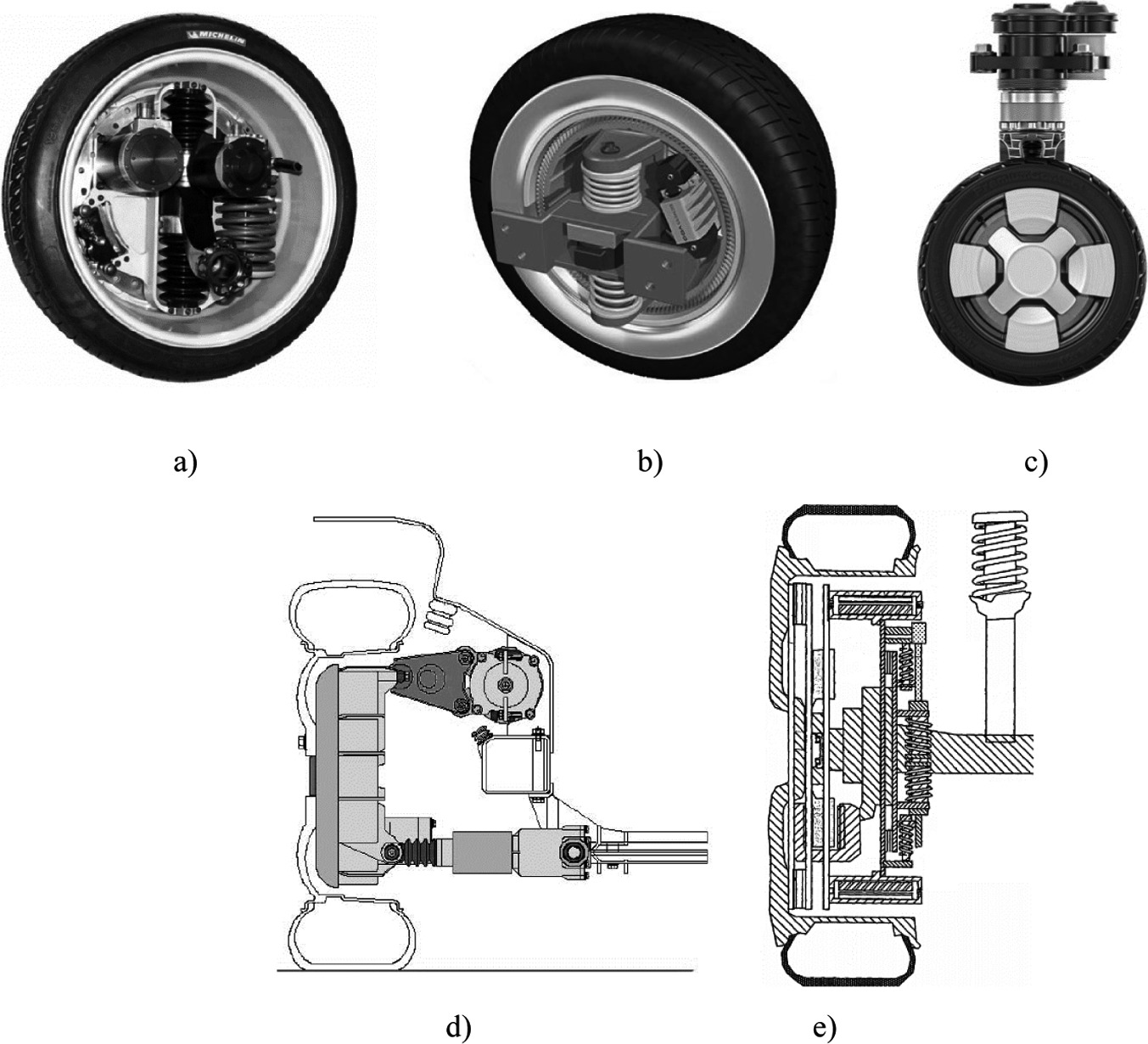

It also cuts weight, which makes for more-efficient travel. This cuts mechanical losses, inherent in every component standing between the engine and wheel, and makes the car or truck run quieter.

So as gasoline loses favor due to price or its pollution, researchers are trying to develop an affordable, durable hub motor that consumers will like. The car, the Lohner-Porsche, could hit speeds of up to 35 mph, letting it set several world speed records.īut technological limitations of the hub motor and a more-appealing alternative, the gas-powered internal-combustion engine (ICE), kept hub motors out of cars and the vast majority of trucks, except for a few concept vehicles. The idea has been around almost as long as the automobile, In fact, Ferdinand Porsche, founder of the famed German auto company, mounted a pair of hub motors that used electricity from a gas-powered generator on a car back in 1900. Stationary windings, usually concentric with the wheel, generate electromagnetic fields which force the outer windings mounted on the wheel to follow them and, thus, rotate. The idea is to build an electric motor right into the wheel. One such approach, the electric hub motor, seems to show promise. Senior Institute (USA), Michelin, Siemens VDO, As engineers strive to devise and refine alternative powerplants for cars and trucks, ones that won’t burn fossil fuels or make each vehicle a point source of pollution, some are looking to the past for inspiration.

0 kommentar(er)

0 kommentar(er)